DM100

DM100The DM100 is a simple to use real-time in-line moisture monitoring and moisture control solution that is ideal for measuring product moisture at the exit of a grain dryer. The DM100 is also capable of basic automatic moisture control.

The standard configuration of the DM100 includes one of Dryer Master's stainless steel fin type moisture sensors, a display panel , a rotary feed chute for mounting the moisture sensor and an optional calibration button.

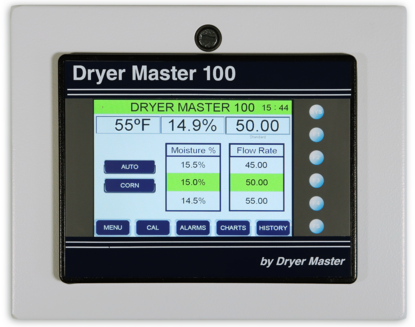

The display panel includes a high performance color touch screen and a Micro PLC. It is used to enter change process settings, enter sensor calibrations and display and store process information.

Data is stored on a micro-sd card inside the enclosure. For easy data access there is a USB port on the bottom of the enclosure. Using a USB stick the operator can download historical process data (in .csv format) for later insertion into a spreadsheet program.

Product moisture is measured by the Dryer Master moisture sensor and then displayed on the DM100 panel. The sensor is simple to calibrate against a bench top manual tester.

The DM100 is a state logic machine, with control adjustments made only when preset triggers are met. The operator inputs high, low, and target moisture triggers for each of three user settable discharge rate speeds and response time settings. Moisture control is achieved by switching between the discharge rate speeds as triggered by the settable moisture targets. This is a system intended for a more hands on style of operation, as the speed set points and moisture targets will need periodic adjustments to maintain optimum performance.

The system interfaces with most modern variable frequency drives directly and usually only requires a small isolation interface to operate non isolated SCR controllers.

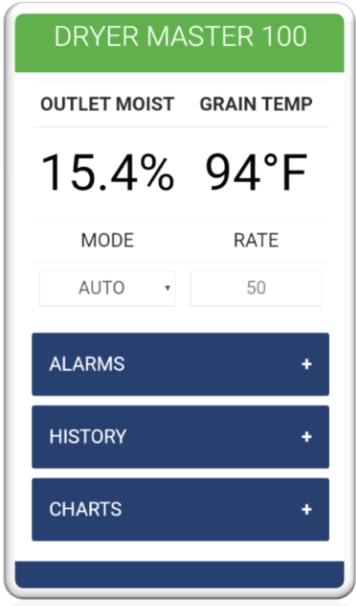

The DM100 comes with a built-in web server allowing process data to be forwarded to a smartphone via a network connection. The smartphone display shows process information as well as process history, alarms and graphs.

Outputs are also available for transmitting the moisture, product temperature, and discharge rate to other automation equipment .

For achieving good results, operator involvement in making and changing the control parameters is important. In general, the system performs best when inlet moistures and drying conditions are relatively stable and where dryer residence times are shorter.