Dryer Master's Moisture Monitor Pro (MMP) has been specifically designed to give the process operator an easy to use method to monitor the moisture of the product they are working with. The MMP can be used with one or two real time moisture sensors.

Product moisture and product temperature are measured by the Dryer Master moisture sensor(s). The signals are relayed to the MMP panel where they are converted to moisture and temperature readings for display on the screen. Calibrating the sensor to your manual bench top tester is easy to do.

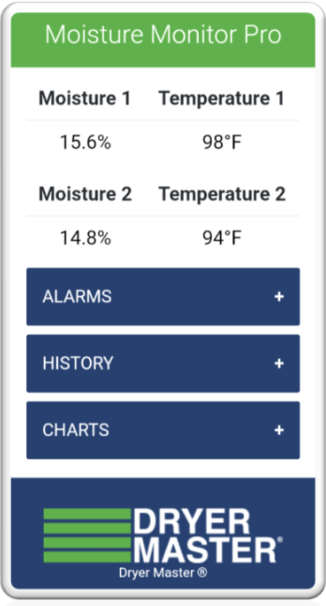

The Moisture Monitor Pro comes with a built-in web server allowing process data to be forwarded to a smartphone via a network connection. The smartphone display shows process information as well as process history, alarms and graphs.

Data is stored on a micro-sd card inside the enclosure. For easy data access there is a USB port on the bottom of the enclosure. Using a USB stick the operator can download historical process data (in .csv format) for later insertion into a spreadsheet program.

Outputs are provided for activating a remote alarm or triggering a process event such as a shutdown or product diversion, when off spec product is detected. Additional signal outputs for transmitting the moisture(s) and product temperature(s) to other automation equipment are also available.

For users without a PLC who would like to have access to real time moisture and temperature readings from their process, the MMP provides a cost-effective solution. The record keeping and remote access capabilities are an added bonus.

Moisture Monitor Pro Product Manual